Our Solution to

Etching HF Waste Water Treatment

Where?

Etching HF Waste Source

Activation / Oxide Removal ✅ (HF enters here) HF or mixed acid dip used when substrate has silicon dioxide, nickel oxide, or copper oxide. Example: For semiconductor wafer: HF removes native SiO₂. For Ni/Cu underlayers: HF dissolves oxides to activate surface before plating.

Etching step (microelectronics, PCB, IC packaging): HF used to etch exposed oxides before gold deposition. Stripping / Rework: If plated part is defective, HF mixed with nitric acid can dissolve nickel/copper underlayer so gold can be recovered.

EQA IER 2009

Regulatory Standards in Malaysia

According to Malaysia's Environmental Quality Act (Industrial Effluent) Regulations 2009, the permissible limit for fluoride in industrial effluent is ≤ 5.0 mg/L for Std B & ≤ 2.0 mg/L for Std A. This means that industries must ensure their wastewater treatment processes effectively reduce fluoride concentrations to meet this standard.

How?

Treatment Methods for HF Wastewater

The primary method for removing fluoride from HF wastewater involves chemical precipitation, where fluoride ions are converted into insoluble compounds that can be separated from the water.

Treatment methods of Etching HF Waste Water Treatment System

pH Adjustment: Maintaining an optimal pH level is crucial for efficient fluoride removal. The solubility decreases at higher pH levels, enhancing precipitation. Typically, the pH is adjusted to optimal pH by adding alkaline substances, ensuring maximum precipitation of fluoride ions.

Coagulation and Flocculation: After precipitation, coagulants and flocculants are added to aggregate the fine particles into larger flocs, facilitating easier separation from the wastewater.

Sedimentation and Filtration: The flocs formed are allowed to settle in sedimentation tanks, and the clarified water is then passed through filtration systems to remove any remaining suspended solids.

Advanced Treatment / Polishing System Options:

In cases where initial treatment does not achieve the desired fluoride levels, additional methods can be employed:Ion Exchange: This process involves exchanging fluoride ions in the wastewater with other ions (e.g., hydroxide) using ion-exchange resins, effectively reducing fluoride concentrations.

Reverse Osmosis: A membrane filtration technique that can remove a wide range of contaminants, including fluoride ions, by applying pressure to force water through a semi-permeable membrane.

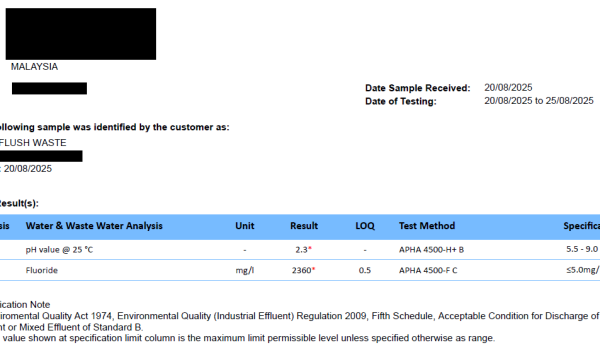

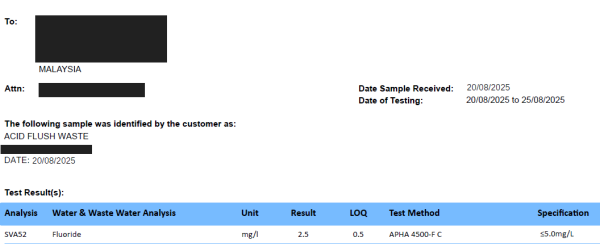

Case Study: Effective Fluoride Reduction

A study conducted by Greentech Alpha Sdn Bhd demonstrated the effectiveness of combining a specialized coagulant, FR-1889, in treating HF wastewater from a wafer etching process.

The initial Fluoride concentration (F-) of approximately 2,360 mg/L was reduced to 2.50 mg/L, within regulatory limit of ≤ 5.0 mg/L (IER 2009 Std B).

Conclusion

Treating HF wastewater in the solar industry is essential to comply with Malaysia’s environmental regulations and protect public health. Employing a combination of chemical precipitation, pH adjustment, coagulation, and advanced treatment methods can effectively reduce fluoride concentrations to acceptable levels, ensuring safe discharge into the environment.

Initial Fluoride = 2,360 mg/l

Treated Fluoride with FR-1889= 2.5 mg/l

Treated Etching HF Wastewater with FR-1889

Features & Benefits

In Greentech Alpha, we offer advanced solutions for industry wastewater treatment systems. We combine the best technologies to provide cost effective and efficient systems for our valuable clients.

HF Waste Treatment

Chemical Reaction & Precipitation

Waste Neutralization

Dissolved Air Flotation

Multimedia Filter

Activated Carbon Filter

Membrane Filtration

Biological Process

Ultra Filtration

Vacuum Evaporator

Consultancy, Upgrading & Maintenance Service

- Consultancy & Technical Services related to Wastewater Treatment System (WWTP).

- Submission of Application to D.O.E. for Approval of Wastewater Treatment System (WWTP).

- Wastewater Treatment System (WWTP) Maintenance Service Contract.

- Repair, Upgrade, Modify & Retrofit existing Wastewater Treatment System (WWTP).

- Our experienced, competent and qualified engineers and technicians are fully capable to conduct classroom and on-site training programmes for your production, project and maintenance personnel on the operation & maintenance of Wastewater Treatment System (WWTP).

- Breakdown maintenance and on-site service.

- Our company offers a service that ensures a 10% annual reduction in the costs associated with the development.