Our Solution to

Industrial Process Water Treatment RODI & Ultra-Pure Water (UPW) Solutions

Scope of Work

Ad-hoc Services (Portable System)

We understand that emergencies can happen at any time. Our team of experts is equipped to handle any emergency situation, and our mobile solutions and rental fleets are available to ensure that we can quickly and efficiently address any issues.

Scope of Work

Advanced Filtration Solutions (RODI / UPW)

Our expertise in this area enables us to offer top-of-the-line pure water treatment services that effectively remove contaminants from untreated water to produce process water pure enough even for the most critical of its intended uses.

Features & Benefits

We offer advanced solutions on physical filtration, membrane technology and ion-exchange technology. RODI / Pure water treatment is the removal of contaminants from various untreated water that helps to produce and process pure water for various usages.

- Ion Exchange

- Mixed Bed Resin (DI System)

- Softener System

- Multimedia Media Filter (MMF)

- Activated Carbon Filter (ACF)

- Ultrafiltration (UF)

- Reverse Osmosis (RO) Membrane System

- Electro-Deionization System (EDI)

- Final Filtration System

RODI/UPW WATER TreatMENT

Service Capabilities:

- Fabrication & Installation

- System Design & Engineering

- Validation & Commissioning

- Routine Maintenance & Membrane Cleaning

- Water Quality Testing & Performance

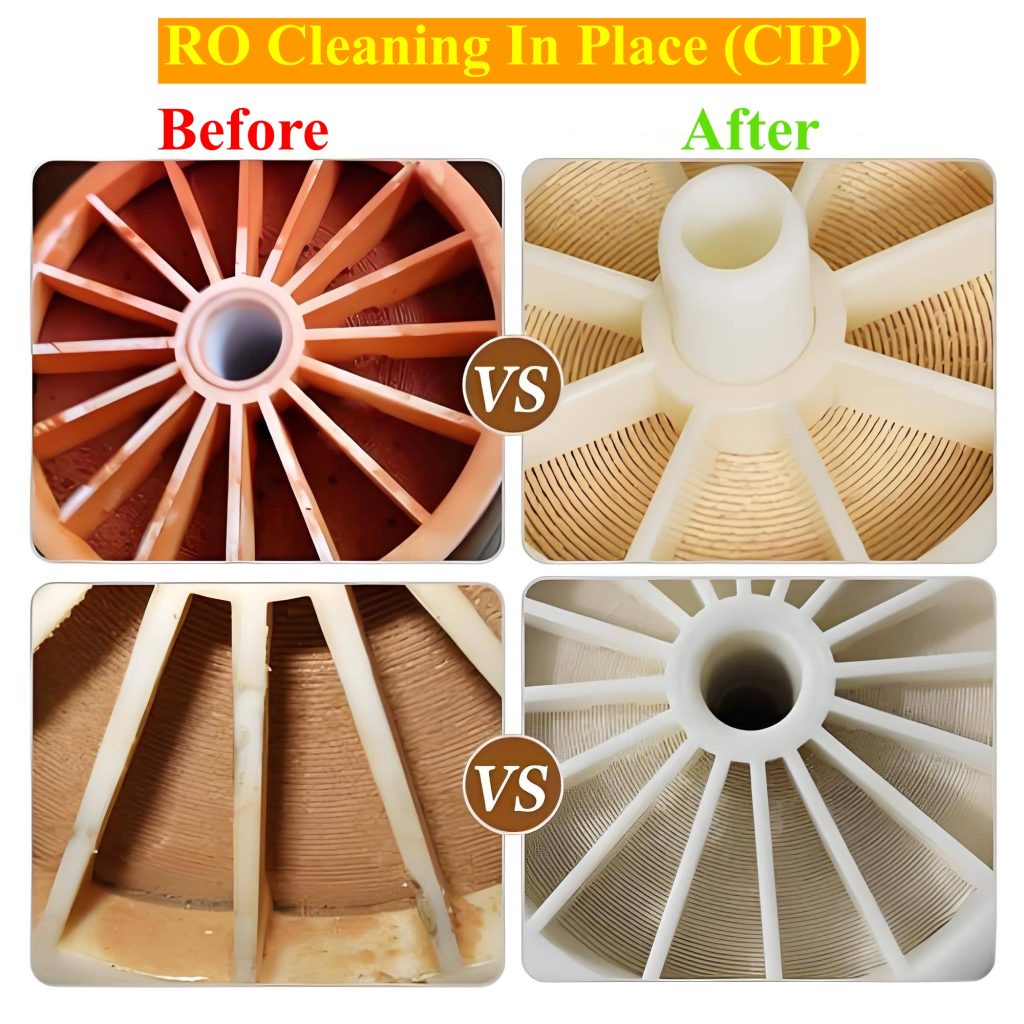

Restore RO Membrane Performance with Expert RO CIP Services

Reverse Osmosis (RO) membrane systems are vital for ensuring high-quality water output in industrial and commercial applications. Over time, however, these membranes become fouled by scale, biological growth, organic material, and other contaminants, leading to decreased performance, higher energy usage, and reduced membrane life.

Clean-in-Place (CIP) is a specialized chemical cleaning process designed to restore membrane performance without disassembling the system. At Greentech Alpha, we offer professional RO CIP services tailored to your system’s unique fouling characteristics.

Why RO CIP Is Essential:

- Restores water flow and pressure

- Reduces differential pressure

- Improves salt rejection

- Prevents costly membrane replacement

- Minimizes downtime and operational costs

Our RO CIP Process:

System Assessment

Evaluation of system performance data and foulant type (scaling, biofouling, organics, etc.)Customized Chemical Selection

Use of acid or alkaline cleaning agents specifically matched to foulant typeControlled Cleaning Procedure

Circulation of cleaning solution at appropriate temperature, pH, and flow rate

Soak cycles for effective foulant dissolution

Rinse with RO permeate or clean water to remove residuals

Post-Cleaning Diagnostics

Compare system performance before and after CIP

Recommendations for ongoing monitoring and preventative maintenance

When Should You Perform CIP?

Regular membrane cleaning is recommended when:

Permeate flow drops by 10–15%

Salt rejection declines by 5–10%

Differential pressure increases by 10–15%

Normal operation cannot meet water quality requirements

Why Choose Us?

✔ Experienced Technicians

✔ Safe & Effective , Food Grade Chemicals

✔ On-Site or Off-Site Services

✔ Quick Turnaround

✔ Compliant with International Standards